1. What Is Project Cargo Transport?

Project cargo transport is an internationally used term to describe the transport of huge, high value and heavy critical equipment globally to the desired location of installation or use.

This is also known as heavy lift cargo transportation and includes shipments of different types of components that need disassembly to facilitate shipment.

These parts and equipment are transported independently and reassembled on arrival to the desired destination.

The definition of a project cargo transport is tied to the nature of load being carried and a combination of an entire set of emerging ideas, creativity and out of box solutions.

Most of these cargoes are usually transported from their manufacturing centers to the installation site or a customer’s premises.

Get Detailed Specifications!

These types of cargoes cannot be transported with the use of normal trucks and that is why specialized trailers such as modular trailers are used for their transportation.

Any cargo that cannot be carried by the usual trucks and containers, it qualifies for project cargo transport. This means that the cargo is a custom design for use in a specific project and thus needs special attention during its transportation.

Specialized transportation is needed owing to their weight or their size or due to both the weight and its size put together. Generally, these cargoes are bigger than the capacity of commonly used transportation containers.

In that case, the cargo is normally moved as it is in its bulk condition. A good example is a wind turbine blade for big wind farms that are usually close to 300 ft long. Ideally, it’s even bigger than the wingspan of the biggest aeroplane.

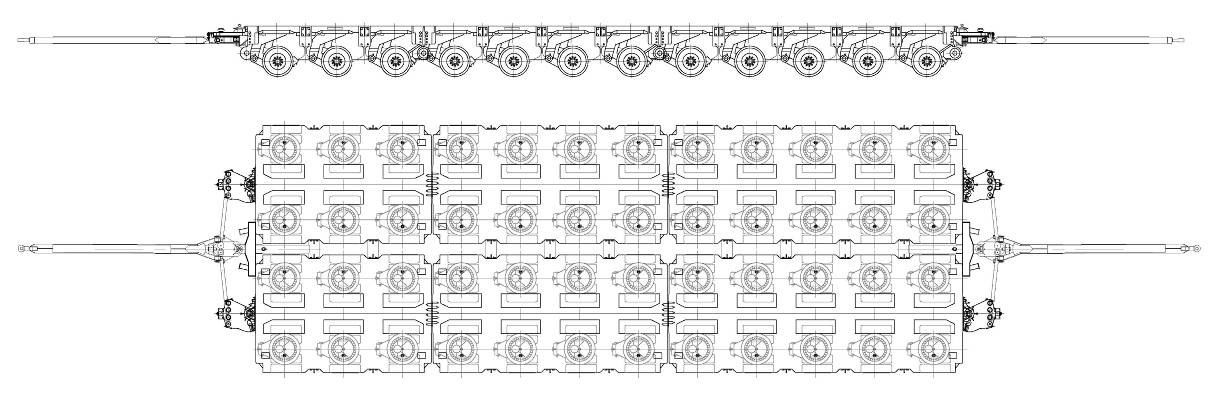

Modular trailer in Project cargo

Learn more: What is Heavy Lift Project Cargo Transportation?

2. Special Vehicles for Project Cargo

Massive cargo on grounds of size and weight needs special transportation modes that are uniquely meant to take up its safety needs and offer the desirable operating efficiency.

Imagine moving the wind turbine blades exemplified above on a sloppy mountain where the roads keep meandering all through to the top. It is impossible to carry such loads on normal flatbed trucks.

Otherwise, if the cargo was to be transported over flat terrain, the flatbed trucks would definitely be used. Even with that, there will still be some issues with such an approach: what would be the length of such a truck?

Owing to the fact that the road up the mountain is curvy and not straight, you will need specialized transportation vehicles commonly known as modular trailers for this kind of operation.

All you need for this kind of transportation is not a suitable vehicle alone. You will also need to conduct a survey of the roads leading to the destination before the merchandise can be allowed to leave the factory.

Some of the things to consider are the width of the road to make sure that it is sufficient.

Check width of road

You must also confirm whether there are bridges along the route and if so, it is important to establish their strength and capability of taking the weight of the trailer and the accompanying cargo.

This is what makes the project cargo transportation process special. You will not just use any truck for it and more than that, the right trailer must be used for this kind of job for a safe delivery of the merchandise.

For modular trailers, you will be forced to widen the road if it is not sufficient to allow its passage with the heavy lift cargo on board.

Some of the items that could be affected along the road are the electricity poles. All these requirements must be assessed and analyzed during a survey of the road which is part of the pre-planning process.

The use of modular trailers requires the acquisition of road permits as issued by the governing authorities within the jurisdiction.

Get Detailed Specifications!

3. What Is the Advantage of Using Modular Trailers

It has been widely proved and agreed upon that a normal container or container cannot take up the project. So, why modular trailers?

Basically, modular trailers come with a number of advantages when used for the transportation of project cargo. These types of trailers operate in a way that traditional trailers cannot do.

A modular trailer has various apparatus attached to it and can be customized to take up a unique load with specific demands.

This type of trailer has a bed coupled on a frame that is made according to a desired length and width. Another additional apparatus is a transportation conveyance that reaches all the way to the ground surface.

There still is another for the same purpose although is connected to the other side of the main frame of the trailer. The modular trailer apparatus could also include a towing arm with a bed feature that is freely coupled to tow it.

To address the issue of unique cargo size and nature, there are many options that come with a modular trailer and that is especially with the apparatus needed to lift and keep the cargo in position during transportation.

In that case, the bed could be connected to the trailer frame and the tow part may be connected to a coupler on the trailer set for the purpose of securely attaching itself to the trailer bed located between an extended and a reattracted position.

All the modular trailers apparatus enhances its usefulness and applicability in the transportation of massive, over-length and super weighty cargo normally noticeable in various industries such as the energy and construction industries.

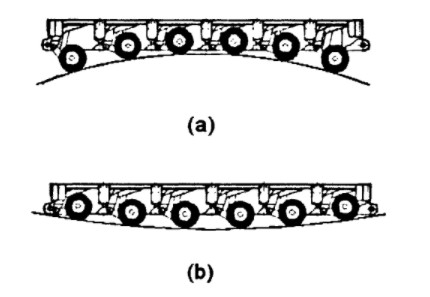

A key feature of the modular trailers is the suspension hydraulic system on the trailer loading platform that keeps it balanced during transportation.

keep horizontality

It helps in safely securing the cargo in position even on a rugged terrain. The design is made to provide excellent damping characteristics that make sure that there is a smooth transit of the project cargo.

Here are some of the key advantages you will find with the modular trailers especially in the transportation of heavy lift cargo:

- Safety

Due to its huge size and weight, the project cargo needs careful attention to its safety during loading, transportation and offloading.

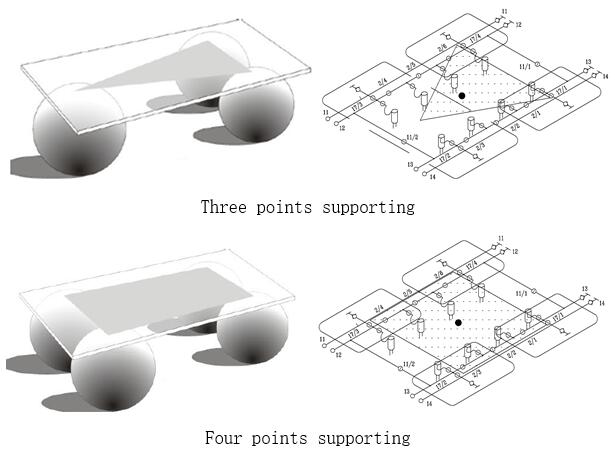

This is what the modular trailer has been designed for. It is very good in keeping the cargo in a horizontal balanced position offering 3 and 4 points of support that take uniform loading forces.

The modular unit uses a hydraulic wheel boogie that comprises a bogie frame, hydraulic cylinder, rocker arm, the tyre and axle that are designed for robust load capacity needs.

On rugged road terrain, the axle is designed to swing to offer compensation and keep the trailer on track. The modular supporting system can also be twisted through hydraulic lifting system to take care of the driving direction on an uneven road.

The steering systems make use of a hydraulic planar pitman drive through adjustments effected on it and a number of rational pitman layouts. Still, the vehicle can achieve a normal drive and the minimum turning diameter as well.

The main supporting elements of the modular trailer are the adopted solid box beam structure. The mainframe longitudinal girder, steering arm, bogie frame and trailer platform are constructed of high-performance welding steel.

This ensures that are no safety concerns when the load is sited on the platform.

Get Detailed Specifications!

- Efficient Transportation

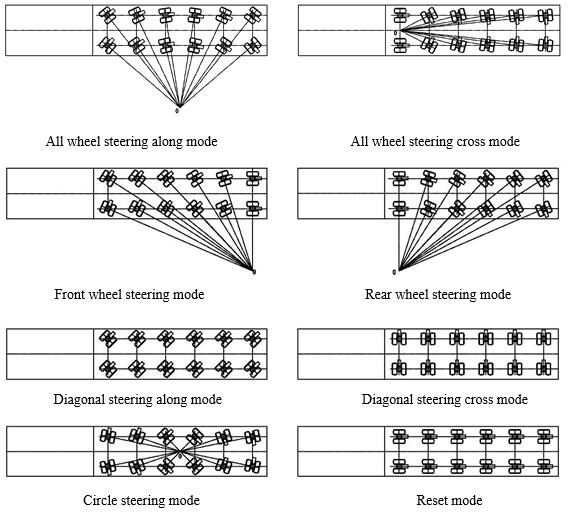

The modular trailer offers effective transportation means a for a project cargo with reliable speeds. The design and building of a modular trailer are such that all the axles can swivel through 270°.

In some cases, you can even find some that can go up to 360° full motion. Looking that the bulky size of the project cargo, features of maneuverability as present in the modular trailer are very useful.

single transporter steering

Each of these axles is usually controlled via a system of controls to facilitate the turning of a modular trailer.

A number of motions can be executed on the modular trailer including allowing it to spin on one location or else move sideways as needed in a specific condition.

Different modular trailers found in the marketplace allow for the axles to telescope independently of each other making it possible for the load to remain flat and at the same time be loaded uniformly over a rugged terrain.

Each of these axles can be made available with an inbuilt hydrostatic drive unit.

Sufficient steering power can also be supplied to your modular trailer with the use of hydraulic power pack. This is also needed for drive and suspensions operations.

The power pack is usually driven through the use of an internal combustion engine. A single power pack can be utilized in driving a number of modular trailers connected to each other.

This makes it possible for these vehicles to take the heaviest loads in the category of project cargoes. They can efficiently move at slow speeds when needed covering a mile per hour, particularly on full-load mode.

Some modular trailers can also be driven by an operator using a hand-held panel of controls as others use the driver cabin for operations.

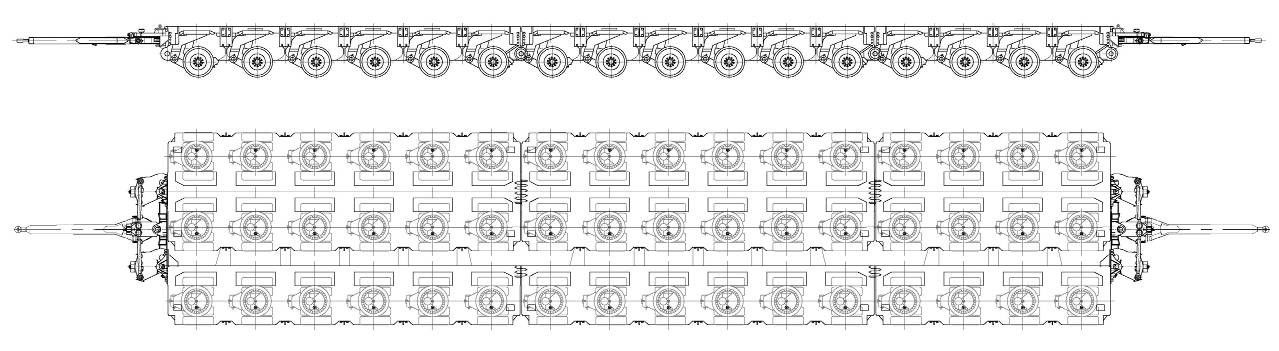

A number of these trailers can be connected lengthwise or side-by-side to take bigger loads as the demand would require. A single control panel can also be used to control the different setups as would be applied in a given operation.

Efficiency in transportation is also enhanced through stable operations. Each of the modular trailer units can be categorized into 3 and 4 hydraulic regions.

spmt support

All the fields can maintain hydraulic pressure to the axles in it. This enables the trailer to make desired adjustments for uneven terrain ensuring the stability of your cargo during transportation.

The low loading height of the transporter coupled with a wide wheel track ensures a greatly enhanced stability too.

Different modular trailer series have double modes like the semi-trailer towing and the full-trailer towing. In a full-trailer towing configuration, travel speeds can be 40Kph where there is a maximum tractive force.

This is specifically applied in heavy lift cargo transportation where low speeds are needed. In a semi-trailer towing, the length of the vehicle is cut down and the minimum turning diameter as well.

however, the effective load gets upgraded in this mode and the speeds too where the modular trailer can move at a speed of 80Kph.

Get Detailed Specifications!

- Meeting Different demands

Due to the modularization nature of the trailer, various cargo demands can be met.

These trailers are completely modular and that means they can be connected to each other either end to end or side by side to provide various configurations for use as the cargo would require.

The end to end or side by side connection is made possible through a mechanical coupling or in some cases, loose coupling.

For end-to-end coupling, hydraulic pins are used whereas special connecting pins are applied for the side-by-side connection.

There is a single set of controls for each modular transporter that can be synchronized for coordinated steering function and other operations as well.

Communication in between the various modular trailers happens through a CAN bus that synchronizes and coordinates the combination working.

3 file combination modular trailer

4 file combination modular trailer

During the communication between the modular trailers, one of them is marked as the master unit as the other trailers are left to get instructions of driving, lifting, steering and braking among other operations from the designated master unit.

These capabilities make it possible for the loading and transportation of a complex and oversized project cargo.

- High Load Carrying Capacity

This is arguably the most defining characteristic of a modular trailer that makes it an appropriate vehicle for the project cargo. Its usefulness begins here – its ability to take up the load.

The main load-bearing frame and the suspension are constructed of 690 MPa yield stress steel material. Ideally, this is the main structure for bearing, taking into consideration the most dangerous cargo condition.

The safety coefficient adopted for the design is 1.5 and that means there is enhanced capability to manage the load onboard without any concerns of failure due to loading.

The key bearing sections of the modular unit, which is the main girder of the frame, the wheel bogie and so on have taken a strong box-type beam framework. The material used is the same of 690MPa yield strength of high-performance welding plate.

The entire frame has a strong strength and great capabilities able to efficiently withstand bending moments in case of concentrated loads.

The absolute lifting length of the modular trailer platform is 600mm, providing a compensation of ±300mm that is sufficient for compensating the axial loading.

On the other part, the suspension cylinder is directly attached to the steer wheel bogie and the joint bearings fully equipped on either end of the suspension cylinder.

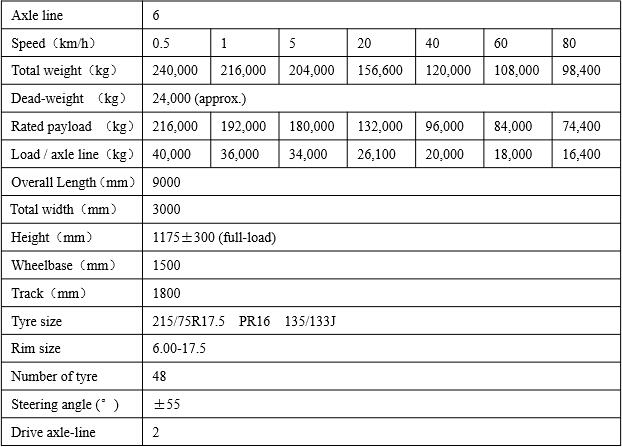

6 axles modular trailer specification

It can protect the cylinder from any form of damage. Again, there is the hydraulic accumulator that provides good cushion once the trailer is unloaded.

The steering system also has a two-way overflow valve that protects the steering system from getting damaged when in an overloaded condition.

Get Detailed Specifications!

4. Conclusion

The need for safe transportation of project cargo has seen a major use of the modular trailer on such applications.

This type of trailer is designed and built to take heavy lift cargo and that is why its suitable for handling unique and custom project parts and equipment.

For a cargo that is not easy to disassemble to facilitate transportation, modular trailers offer a reliable solution. With it, lengthy equipment can comfortably be loaded on it and transported to desired destinations.

Any load than a normal container or truck can swiftly be moved with the use of a modular trailer.

Such industries as the power industry, wind turbine installations and many other types of project cargo have widely used modular trailers due to the advantages highlighted in here.

The transportation of these types of cargoes need good stability and maneuverability, that is normally offered with the use of a modular trailer.

These trailers have a very good steering system that can easily manage these heavy loads without causing any safety concerns during transportation.

Project cargoes have special features and custom designs that may not fit in conventional trucks and containers.

For that reason, the modular configuration of these trailers makes it possible to couple several of them in a way that is desired to fit a specific project cargo type.

The custom solutions offered through the use of modular trailers make them very useful when it comes to such kind of transportation.

In places that are bumpy and rugged, a modular trailer will perfectly handle the operation keeping the cargo balanced throughout.

Its strong high-performance steel structure has the load bearing capacity that can match the needs of many project cargoes. These factors are what makes the modular trailer a good choice for project cargo industry.