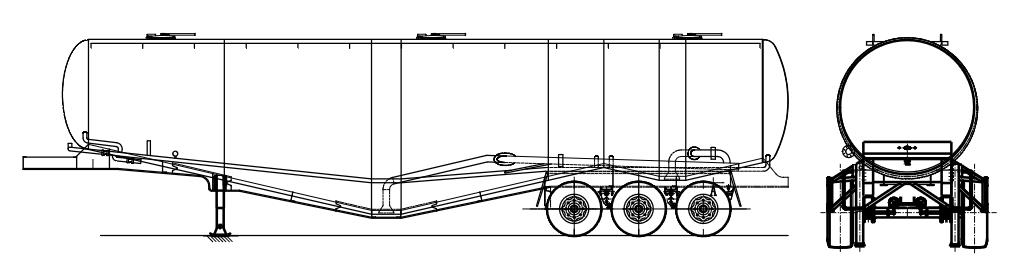

The dry bulk cement tanker trailer used for transporting cement is a bulk powder transport vehicle made of a combined specially designed chassis, pneumatic piping system, tanker and discharging units.

This design is specially made for the safe transportation of bulk cement commodities, lime powder, coal powder and any other dry powder material that has a particle diameter of less than 0.1mm.

Its common application and use are in the cement manufacturing factory, construction sites and the cement warehouse. With the use of this type of trailer, packaging and discharging costs are greatly reduced.

Contact us, get more specs now!!

1. Why Use Cement Tank Trailer to Transport Dry Bulk Cement?

- Simple and Convenient

It can transport a lot of cement at once. Most importantly, it ensures that the quality of the cement in transit is safe from any dampening.

No much of packaging and unpacking is needed with the use of a cement tanker trailer. The process of loading and unloading cement from the tanker is simplified through the fluidization process.

- Effective and Reliable Delivery Speed

The transportation of high amounts of cement can be done at reliable speeds. The trailer offers an effective means of transportation taking up huge volumes of cement at ago.

This saves a lot on transportation costs. Everything is designed to ensure efficient transportation and delivery of large volumes of cement efficiently and in the shortest time possible.

Contact us, get more specs now!!

- High Load Carrying Capacity

The cement tanker trailer takes up to 95 cubic meter capacity per set.

It provides a perfect solution for the transportation of high volumes of cement especially for heavy construction projects unlike using traditional cement transportation means that may not be sufficient for handling large projects.

95 cbm cement tank trailer

2. What Is Fluidization Principle

Cement tank trailer’s working principle is based on Fluidization principle.

When the mixture of gas and powder reaches a certain proportion, the powders will have some liquid properties hence attaining fluidity.

Fluidization is a process comparable to liquefication in which granular materials get converted to dynamic fluid-like states from their original static solid nature. This normally happens when a gas or a liquid is passed up and through a granular material.

When gas flow gets introduced via the bottom of bed carrying solid particles, it tends to move in an upward manner via the bed through the empty spaces existing in between the material particles.

When the gas velocities are low, the aerodynamic drag on each of the particles is also low hence the bed is kept in a fixed state.

At high velocities, the aerodynamic drag forces will start to counteract the gravitational forces and make the bed expand volumetrically as the powder particles begin to pull away from one another.

With a continued increase of the velocity, a critical value will be reached where the upward drag forces equal the downward forces of gravity.

At such a point, the particles will get suspended inside the fluid. This is when the bed is considered to be fluidized and will show such behaviour. A further increase in the fluid velocity, the bulk density of the trailer bed will show fluidic behaviour.

If the gas velocity continues to increase further, the bulk density of your bed will keep decreasing and the fluidization gets more violent.

This will continue to a point where the particles no longer form a bed and are taken upwards through the flow of the gas. When the bed is fluidized, solid particles on it will start to flow like a fluid.

Just like a liquid in a bucket, the bed will take the volume of the chamber as the surface remains perpendicular to the force of gravity.

Objects that have a lower density than the density of the bed tend to float on the surface, bobbing up and down when pushed downwards.

Higher density objects will, however, sink to the bed’s bottom. Through this fluidic behaviour, the particles will be transported like a fluid channelled via pipes without the need for mechanical transporter such as conveyor belts.

A much-simplified form of a gas-solid fluidized bed is the hot-air popcorn popper. The popcorn kernels are usually fairly uniform in shape and size and get suspended in the hot air that rises from the chamber’s bottom.

Due to the intense mixing of the particles in it comparable to that of boiling water, the kernels in the chamber attain uniform temperature hence minimizing the number of burnt popcorn.

Contact us, get more specs now!!

Once the popping has been completed, the bigger popcorn particles get increased aerodynamic drag that pushes them out of kernel chamber into the bowl.

The process is responsible for the formation of sand volcanoes and fluid escape structures in sedimentary rocks and sediments.

Read More: Fluidization – Wiki

3. Fluidization Principle in Cement Trailer

The compressed air will go into cement tanker from an air compressor. Then gas gets through the fluidized bed to make the powder into a fluid-like state.

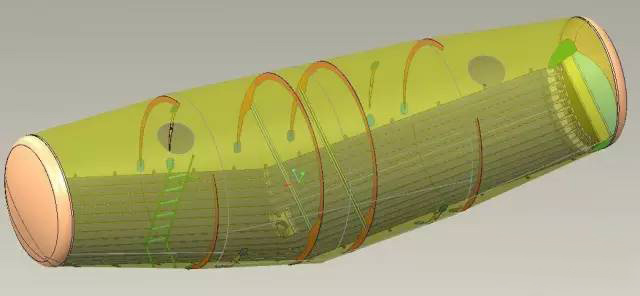

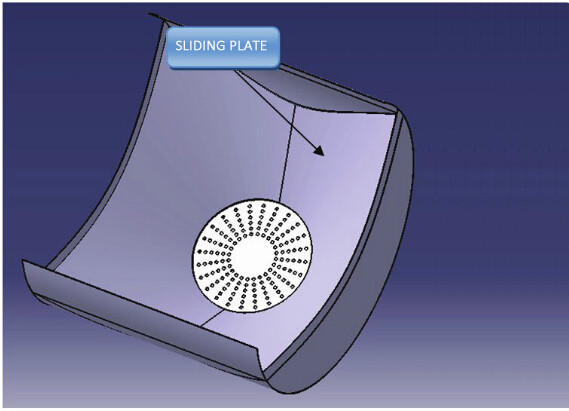

The tanker of the cement trailer comprises a tanker body, a fluidized bed, upper entrance, air pipings and discharging kits among other components.

Usually, there are 3 upper entrances situated at the tanker’s top. For the tanker’s air piping system, one air entrance pipe is situated at the front and another one to the back. These are separately controlled through a ball valve.

Once the power is turned on and gets transmitted to the air compressor, the air, once condensed will flow straight to the tanker to fluidize the cement powder.

When the pressure gets to 0.196 Mpa, the butterfly valve can now be opened to allow for discharge. Here are important things to take note of when the dry bulk cement tanker trailer is in operation:

- The compressors’ working pressure is 0.2MPa that should not be exceeded as a result of limit pegged on overload or over-speed driving.

- Don’t change the spinning direction of the unit’s air compressor

- Maintenance should be conducted after 30 hours of operation to clean the air filler that should be changed once 5 maintenance times have been reached.

This trailer is particularly useful in the transportation and offloading of bulk cement that would otherwise clump and clog following a slight compacting.

Contact us, get more specs now!!

The trailer has a completely enclosed compartment that holds the bulk cement material, an air vent at an upward section of the compartment and has a base floor to the specific compartment fitted with means of injecting air that is compressed.

The air under pressure travels through the cement and exits at the vent section. It serves to mobilize and at the same time fluidize the cement material in the compartment.

Once the cement is fluidized, it can now flow via gravity down in the direction of the exit as it gets offloaded from the tanker trailer.

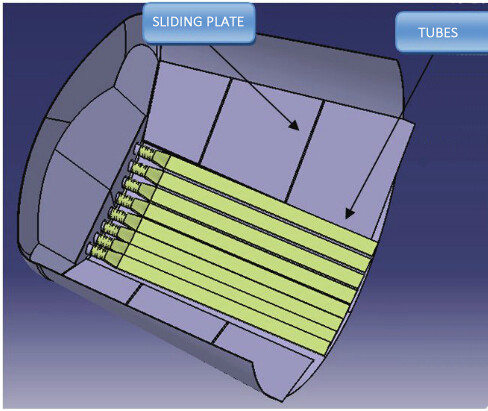

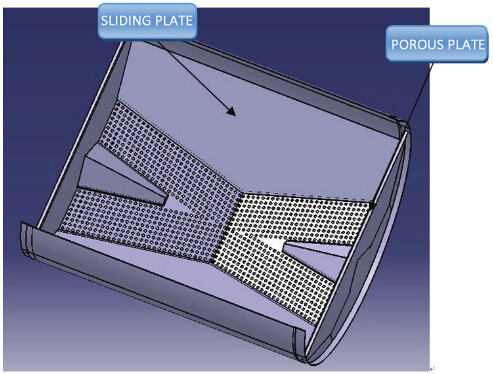

This type of trailer is usually converted from a traditional rectilinear combination or a from a box trailer through the inclusion of a double set of pipes located in the floor.

The pipes are normally supplied with air outside the tanker trailer during offloading as the trailer gets tilted in an upward direction standing on its rear wheels.

This allows the floor to slant in the direction of the rear section as an exit manifold is present to pump out the fluidized bulk cement.

Fluidized bed of cement tanker

tubes fluidized bed

x type fluidized bed

funnel fluidized bed

More details of fluidized bed for cement tanker:

What is a powder pneumatic / bulk cement tank trailer?

Preparation for the Fluidization Process

There are important checks to make to ensure that everything is working on well in the pneumatic trailer. Once this is confirmed to be working well, you can now proceed to engage the trailer to perform the desired function.

- Start the power take-off (PTO) of the trailer and the air compressor needed for blowing air directly into the cement silo. Make sure that the compressor is not turned on when it is already sufficiently loaded. This is very important.

- Increase the velocity of the truck to the required rpms for the desired compressor operation.

The rpm of the truck must be sufficient enough to support the operation of the compressor onboard. Additionally, the unit must be running smoothly.

The reading on the compressor’s oil pressure gauge should be ascertained. More than that, checks should be conducted for any noise that could be emanating from the mechanical setup.

Checks on the air filter should also be done to ensure they have the correct reading as a set. There shouldn’t be any loose parts and noticeable air leaks within the unit prior to conducting an operation on the pneumatic tanker trailer.

- The boost valve of the system should be closed to help in pressurizing the tanker to the desired working pressure for the cement tanker. It is important to attain the recommended pressure for a smooth operation.

- After that, open the boost valve and then open wide the rear outlet valve suddenly to begin offloading cement directly into the trailer’s silo.

pneumatic tanker trailer operation

Fluidization Checks to Make

After making the necessary preparations, it is time to follow the process and ensure that everything goes as planned. It is important to monitor the process to be sure of getting the desired results at the end of it all. Here is what to do:

- As the discharge process goes on, a close look must be kept on it.

All throughout the process, the tanker pressure should always be kept below the maximum set value. The pressure of the tanker will seek to open the boost valve when the oncoming pressure is high.

When the pressure is low, the boost valve will on the contrary close slightly.

- The tanker pressure should also be checked to take note of when it will suddenly drop. Should that happen, close up the discharge valve.

- The pressure of the tanker is usually built by opening up the aeration valve, located next to the cone, closing aeration valves and the boost valves. These steps should be followed until the tanker is empty.

- Sometimes, some of the bulk cement may fail to come off completely. To address this situation, clean up any residue cement from all the cones after completing the normal discharge process from the silo.

- After that, any residue tanker pressure should be drained off.

This can be realized in the silo or via the use of the tanker dump outlet valve. Open the boost valve, lower the rpm of the truck and let it idle out as you blow air into the silo.

Contact us, get more specs now!!

This process is mandatory to cool off the compressor. After that, the PTO can now be disengaged. It is important to make sure that the compressor is not turned off when loaded.

- Next, ensure that the discharge valves are closed down and leave the air dump and boost valves opened for the next loading. You can also choose to disconnect the hose for hot air off the tanker.

- When there is an emergency, each of the discharge valves should remain closed. After that, open up the emergency dump valve situated at the compressor exit. Once this is done, the compressor can be shut down.

bulk cement trailers discharge outlet

Read More:

Powder / Bulk Cement Tank Trailer Guide – How to Choose Specs/Capacity/Dimension

4. Conclusion

The safe transportation of large volumes of powdered products such as cement became a huge possibility with the introduction of the dry bulk cement tanker in the transportation industry.

It is a pneumatic trailer that makes use of a fluidization to help in the delivery of cement and other such-like products to their desired destinations.

Unlike in conventional approaches, the amount of cement that can be transported in one trip is a lot to serve the needs of a large project. This makes it an effective and cost-friendly process of transporting cement around the world.

The fluidization process has been key in realizing such efforts.

This basically is a unit operation where the fine cement particles are changed into a fluid-like state by way of contact with pressurized air from a compressor installed within the tanker trailer.

At certain air velocities, the air under pressure offers the support needed for the cement particles, providing them with the freedom of being mobile without any entrainment.

The fluidized bed in such a set up takes the form of a vigorously boiling liquid.

Here, the cement particles go through a very turbulent motion that further increases as the air velocity increases. Generally, this presents a faster way of transporting and unloading cement.

Article good. But failed to properly describe about aeration net/tubing which is the most important part.

Thanks for your comment, we will publish a new revision soon.