One of the most popular ways of shipping goods in the world is using containers. If you are keen on the road, you will notice so many container on chassis trailers.

Many companies prefer to transport their products in containers. Why are containers so popular? Why is their structure important to you?

You need to know the structure and design of containers to understand their popularity. Knowing the structure of different containers also helps you choose the right container for your business.

If you are a producer or supplier, the knowledge of structures will help you pack and secure your cargo properly. Wrong packaging of goods could lead to damages when they are in transit.

In addition, knowing the structure helps you determine the loading capacity of the container accurately. Did you know that some containers have a tunnel at the bottom?

Keep reading for more details about the features and the purpose of the tunnel.

- Container structure

Most of the containers you will see on the road are standard containers. Standard box containers have a steel framework that determines their load capacity.

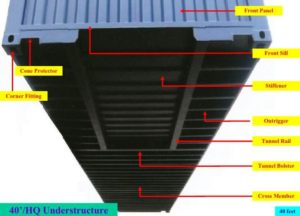

The framework has four corner posts. It has two rails at the top side and other two at the bottom. It also has an end rail on the front side at the top, two cross members at the bottom, and a door header.

Bottom cross members are added to the bottom side rails to provide support to the floor covering. Standard containers have side and end walls that bear the least load capacity.

The materials used to construct these walls cannot carry heavy loads. Hence, containers are supposed to be packaged and transported in an upright position. The side and end walls can be damaged if a container full of cargo topples over.

Other important components of containers include locking components for sealing and door bar handles. Others include a door gasket, door locking bar, cam keeper, upper corner and lower corner casting.

The container floor consists of the bottom side rails and bottom cross member with a gooseneck tunnel. The dimensions and structure of the corner casting vary depending on the international shipping standards used.

Hence, if you intend to use containers, check the standards that apply to your country for the right dimensions. The corner castings must be strong enough to withstand the pressure exerted when containers are stack together.

If you check the side walls of containers, you will notice they have labels showing their capacities. The labels give directions to companies that transport goods with containers.

They show how each container should be stacked others. The labels also show the loading capacity of each container. International standards outline that containers must have such labels for safe transport.

When containers are stacked, they must be protected from shifting and toppling. The main materials used to make containers include aluminum, steel and plywood.

Hence, there are three types of containers including aluminum containers, steel containers, and plywood containers.

The names suggest that the largest part of the container framework is made of that material. However, the truth is that most containers are made of more than one material.

For instance, plywood containers are reinforced with glass fiber-reinforced plastic. Some aluminum containers have a plywood inner lining. Most container doors are made of plymetal, which is a combination of sheet metal and plywood.

- Features of a container trailer

Container trailers have different designs depending on their intended use. The type of containers and means of transportation determine the design of the container trailer.

Some containers are stacked together while some are transported one at a time on the highway. Rail transport is also used to move some containers. Hence, the design and materials of trailers must suit the means of transport.

The structure of the container trailer also depends on the transport regulations in the destination. Some countries specify the maximum height of container whether stacked or moved one at a time.

Container trailers have a strong framework or chassis with a deck where the container is placed. Most manufacturers use steel to make the framework.

Container trailers have their own braking system. They have a hydraulic drive system that controls the braking system and the movement of the wheels. They require strong and durable tires that withstand the heavy weight of container.

Container chassis have different structures. The chassis can be categorized into two major types. The first type is the flat or straight chassis trailer while the second is the gooseneck trailer.

The straight frame chassis have a higher resistant. They are built for rapid container handling and transportation. The straight chassis trailer is long lasting and is suitable for carrying standard containers.

It is used in countries that have no height limitations. For countries with height limitations, the best container trailers to use are gooseneck container trailers.

A gooseneck frame trailer can handle the toughest loading demands. It is suitable for carrying stacked containers or high-cube containers.

- Why container trailer have a tunnel at the bottom

Container trailers are designed depending on their purpose. The gooseneck container trailers have a unique design. Their goosenecks are matching with the tunnels of containers at the bottom. The trailer can be used to transport high-cube containers.

High cube containers look like standard containers but they are taller. Standard containers have an average height of 2591mm. High-cube containers on the other hand have an average height of 2896mm.

When packing the trailer, the containers are centered at the tunnel. The containers lie lower on the chassis because they are placed on the tunnel. Hence, the trailer can be used to carry taller containers than a standard straight trailer.

High-cube containers can be transported with flat container trailers. However, flat trailers can only be used for this task if the country has no height limitations.

Gooseneck container trailers are used in countries that have a limit for the maximum height of containers. Because of the tunnel, the largest containers can be carried with gooseneck chassis.

If you want to buy a container trailer, you must find out the transport regulations in your area. A wrong choice will mean that you cannot transport some containers because of height limitations.

It is always safer to buy gooseneck trailers because you can use them for any purpose. They have the highest capacity to handle the heaviest and tallest containers.

- Conclusion

Containers are made of different materials including plywood, steel, and aluminum. For most of them, two or more materials are combined to increase their strength.

The design and materials used depend on the intended use. Most manufacturers use standard dimensions as outlined in international standards.

Similar dimensions are used because containers are stacked together during transportation. Container trailers are used to move the container from the port or from the manufacturer to the final destination.

The major structures of container trailers are flat or straight frame trailers and gooseneck trailers. The main difference is that gooseneck trailers have a tunnel at the bottom.

The tunnel enables gooseneck trailers to transport high-cube containers because they lie lower. Hence, transporters can abide by the transport regulations on the maximum height of containers.