Modular trailers with an international outlook are the number one selection by customers around the world. China modular trailers have ensured a world-class quality through a major emphasis on high-quality designs and specifications.

This has been a culmination of many years of research, manufacturing and verification procedures. A world-class quality product is adapted to facilitate operations in different conditions.

Now, China modular trailers are fully compatible with Goldhofer Trailer, Scheuerle Trailer.

Being in the industry for a very long time has led to the production of high-end modular trailers matured through a thorough production system.

Attaining international standards has been made possible for China modular trailers through practical use testing and verification procedures.

The design and structure is informed by the need for high configuration, high reliability and high strength in the construction.

The structural parts of these trailers are made of high-strength steel and are perfectly welded to produce a robust construction.

To further enhance the reliability of these modular trailers, the main components of the modular trailers are from renowned vehicle brands such as Dimler Chrysler, Deutz, Rexroth, etc.

Here are more details about modular trailers:

Best Modular Trailer Manufacturers (Hydraulic Axles Trailers)

What is a Modular Trailer? – Learn Hydraulic Modular Trailers Specs & Designs

Contact us, get more specs now!!

1. China Modular Trailer From ANSTER

A world class modular trailer must pass international tests on safety performance. To achieve this, China modular trailers have been tested in collaboration with other bodies across the world.

This is particularly on matters of quality as defined by the ISO quality management system instilled and applied through the entire production process.

ANSTER modular trailer

- Quality tests: Conditions testing are normally conducted on this equipment over a year for a number of different test items. For instance, the China SPMT has a total of 30 test items conducted over this time period. This is carried out to mature the performance of the trailers and make them applicable in different parts of the world. Tests are usually done on loading, offloading, heavy loading and overloading on different grounds. The durability and use of modular trailers on sloppy grounds are also ascertained. Both local and international tests are conducted through a standardized testing process that meets the requirements on the global sphere.

- Performance Characteristics: The performance of a modular trailer is very vital to clients and therefore, the steering and control features are an important aspect in the construction. The source of driving power and the hydraulic systems installed put together ensure faster travelling speeds in the movement of cargo. The ability to produce modular trailers with faster responses in steering and lifting operations has made China modular trailers a world-class construction. They are well-synchronized and equipped with a faster ratio reducer to provide a bigger driving force.

- Hydraulic Technology: This is a very special feature that distinguishes most China modular trailers. Through it, they have become a unique innovation and useful equipment in the loading and transportation of heavy weight cargo. Over the years, there has been a diverse exchange of technology through local institutions and international conference. The desire to address real engineering needs in the transportation industry prompted the push for new and less-sophisticated systems that are economically feasible. This technology has enabled precise positioning, loading and movement of cargo.

- Steering capabilities: High-axle loading demands stable steering operations. China modular trailers have advanced in this aspect and have continued to provide equipment with high steering resistant moment. Additionally, they offer axial force containment abilities and can safely handle the overturning moment, the torque and the radial force or any other intricate joint effect. It is a development that has also matured the trailers’ design hence boosting the reliability and confidence during operations.

- Load-Bearing Abilities: The need for high-end modular trailers to transport heavy weight cargo is ever on the increase around the globe. As a result, China modular trailers have continued their developments in this area by providing a robust frame that can withstand high loading operations. Ideally, the frame is the most important trailer feature because it is meant to take this weight during loading, transportation and offloading operations. The frame design and construction also factors in the stitching precision and the steering accuracy. In that case, the frame construction end goal is not to provide an end-to-end connection. Quality in the construction of the frame structure has been enhanced through automated Computer Numerical Control (CNC) milling procedures. These are more advanced technologies than the conventional integrated structure that has been use over many years. Any issues of deformation are well-taken care of.

Contact us, get more specs now!!

2. Hydraulic System

China modular trailers have continued to offer economically feasible solutions through hydraulic controls and systems. This has largely eliminated the need for having power pack and related systems.

The hydraulic system has five main parts with different functions and specifications: the hydraulic cooling system, the hydraulic brake system, the hydrostatic drive system, the hydraulic lifting system and the hydraulic steering system.

- The Drive System: The hydrostatic drive system is a closed-loop system of hydraulics installed with a variable drive pump. The drive systems make use of pressurized liquid to power the modular trailers. Hydrostatic makes reference to the transfer of power from pressure and flow of the hydraulic fluid. The hydrostatic drive does not involve the kinetic energy in the flow.

- The Steering System: Modular trailers need highly enhanced steering system to manage the loaded weight. The steering system of China modular trailers is an open-loop system that has a variable pump as well. The variable pump plays two major roles: load sensing, and controlling pressure of the liquid flow. Ideally, it can make adjustments to the output flow of based on the existing load needs. The flow adjustment is meant to save energy. On the other hand, the cutting off of flow pressure allows the driver to contain the maximum output pressure of the variable pump. The need for restricting the pressure is so that the hydraulic system can be protected from possible damages.

- Cooling system: The cooling system has two gear motors used for driving fans needed for cooling the composite radiator. Again, there is a gear pump that is used for the supply of hydraulic oil under high pressure to the two gear motors.

- The Brake System: The brake system in these China modular trailers and the parking brake work function by pushing the brake cylinder and releasing the drum. The brake cylinder is fitted with springs that keep the trailer in the parking position when the cylinder is doesn’t have pressure oil. The braking system is also installed with a manual pump used for releasing the parking brake when there is absence of power.

- The hydraulic suspension: Hydraulic suspensions are divided into various wheel bogies: those with brakes, those without brake and those with drive. A suspension in this hydraulic model has a hydraulic cylinder, axle with drive, axle with brake or axle without brake, tire, rocker arm and a bogie frame. The gear shaft sleeves are firmly welded onto the frame of the bogie and a hydraulic suspension cylinder located between the bogie frame and the rocker arm. The cylinder is used to connect the two units together and bear the load, giving the hydraulic suspension system an allowance of ±350 mm for adjustment.

The motor and the reducer are attached on the wheel bogies with drive to offer the modular trailers with the driving force. For the wheel bogies with brake, the axle with brake is attached on the brake cylinder.

The cylinder contains parking and service brake for the trailers. The various types of wheel bogies for the modular transporters have a mechanical stopper that controls the maximum position.

The stopper makes use of the minimum hydraulic suspension cylinder stroke in order to control the lowest position.

The lowest position of the hydraulic cylinder position is locked using a pin. The pin is also applicable to transporting vehicles, during replacement of tires and in the repair of axles.

During the replacement of tyres of fully loaded and offloaded modular trailers, the trailer is brought to a low level. The locking pin is then located into the wheel bogie for the tyre that needs replacement.

What follows after that is the shutting off of the ball valve in the suspension cylinder and lifting off the trailer to replace the tyre. Once the tyre has been replaced, the trailer is lowered down yet another time to its lowest position.

The locking pin is then removed and the ball opened before the trailer is taken back to the driving height.

3. Modular Trailer Key Feature

The hydraulic lifting and the steering configuration is that the two share the same open-loop variable pump. The hydraulic fluid flowing from the variable pump is directed and shared in equal volumes between the steering and lifting cylinder.

This allows the working platform of these modular trailers to lift evenly and causes them to remain horizontal during and after the lifting process. This ensures that operations are conducted while at a leveled position.

Important Considerations to Make

- Material and Welding

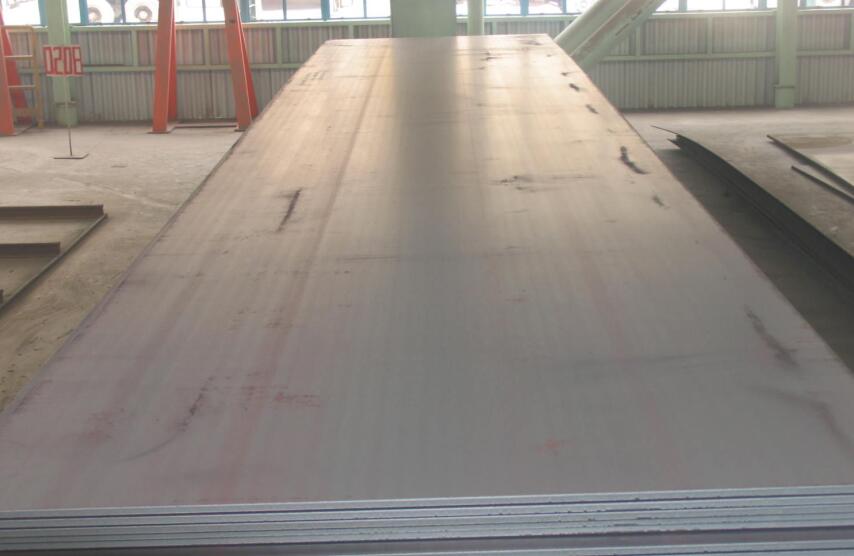

Material: Strength and durability of structure is much needed in the construction of modular trailers and this has been a key consideration by Modular Trailers.

The commonly used grade of steel is the Q690 with a yield strength of 690MPa. It is a high-strength material that comfortably suits the structure and design of these modular trailers to provide the desired load-bearing capabilities.

Particularly, the frame structure is the main and basic component of the modular trailers.

Q690 material

It is designed and manufactured to bear the most dangerous loading condition with a safety coefficient attached to the design adopted for the construction of the various modular trailers.

This material has an ability of withstanding high bending moment under any loads especially with the concentrated load.

The middle longitudinal beam of the frame has a trapezoidal box structure with perfectly oscillating cylinder cases welded together with the frame into a whole construction.

Welding: welding is a very essential process in the production of world-class modular trailers that can be used anywhere in the world.

China modular trailers are used high-quality welding technology that guarantees the accuracy of the frame and construction.

Making an effort to weld all the plates and the beams can be tedious and many people tend to use short cuts in such a process.

This ends up compromising the quality of construction being made. Therefore, the inspection of welded joints and parts should guide any buyer in determining the quality of trailer they are considering to purchase.

Welded sections should be uniform and smooth free from rough surfaces caused by heat deformation. All joints should therefore be checked for the rough surfaces.

Inspection for penetration to neighboring beams and cracks should also be done. All these requirements are met for the China Modular trailers and have attained an international reputation owing to the standard procedures applied.

Contact us, get more specs now!!

- Worldwide Approved

ANSTER Modular trailers have been accepted around the world and that implies that they meet most standards as set around the globe.

The requirements of design and construction match or even surpasses the set standards in most nations hence a reason why the modular trailers have found major application in many parts of the world.

Customers can comfortably rely on these high-quality and reliable modular trailers because they meet the set minimum requirements for heavy haulers in the world.

Euro customer

- Control Precision

The high control precision is a selling point for China modular trailers offering a precision that is less than 2mm in most cases.

This implies that these trailers can easily be maneuvered to reach the desired loading position and in making smooth movements during operations.

This has been a continuous work of design over the years engaging the best minds in the industry.

Professional approaches to the development of these modular trailers have been applied both in structural design and in the development of good control software.

remote control

One of the biggest challenges with the use of heavy haulers is putting in place good control mechanism that are very precise to enhance accurate loading, transportation and offloading operations.

The development of the module vehicle steering system gives them an upper hand in the international marker over other trailers. This design is more reliable and scientific, offering the best desired solution in the world of heavy haulers.

- Compatible with other Famous Brands

The development of the China modular trailers has been an advancement of the work that has been achieved in the past in the construction of heavy transporters.

The only difference is that, these ones offer a superior functionality than the former. It therefore means that they are still compatible with other brands already in existence in the market.

If you had another brand of a modular trailer, you can use it in tandem with China’s modular trailers. You will still be able to make use of other brands together with these options when transporting your cargo.

compatible with goldhofer

- Advantage Design, cooperate with professional college.

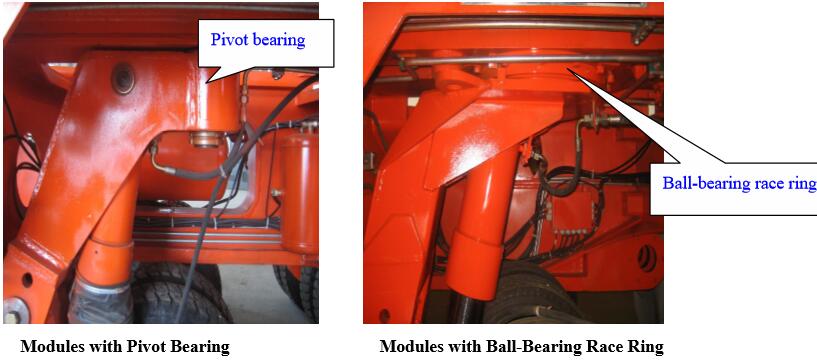

The technology team develops different bearing types for clients to choose from. One of the defining features of a modular trailer is the type of bearings installed.

There are two types of modular trailer categorized based on bearing: Pivot Bearing and Ball Bearing Race Ring.

- Pivot Bearing Type – this is commonly used for light weight capacity modular unit. 23T-25T. Be ready with information on your weight specifications and settle for this if the tonnage is within the given range. There is no point of getting a bigger one while this can suffice. Despite the light weight operations, this type can also offer you with a wide range of applications. It can be used for construction site operations and in public roads as well. This is usually for extremely low dead weight with features of big tires that makes it suitable for off-road use. It also has technical features offering good bending moment that enhances your operations on the different locations.

- Ball Bearing Race Ring – this is commonly used for heavy load modular unit 30-45T. Don’t buy a modular trailer type that cannot handle your weight needs. If this is the weight range of your cargo, don’t force it on the pivot bearing type. Instead, go for the ball bearing race ring. With this type, lifting your heavy loads becomes possible. You can use it in public roads and operations within your plant. It gives you an optimum ratio for the payload versus the axle load. Another important feature is the torsion-resistant frame that comes with a closed loading platform facilitating the carrying of concentrated loads as well as heavy-duty cargo in the drop deck.

This is a perfect idea that will help you make the right choice of a modular trailer without being wasteful as informed by the type of cargo you want to handle.

modular unit wheel bogie steering

Contact us, get more specs now!!

4. Ensuring Safety Hauling

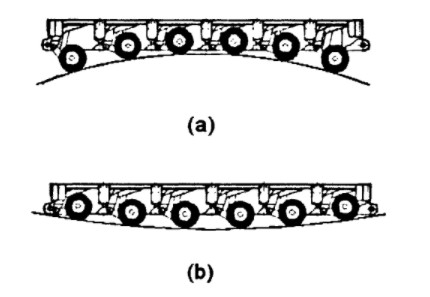

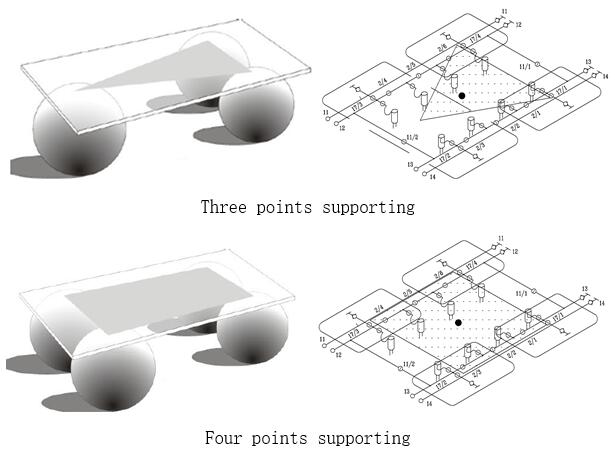

The hydraulic suspension is used to keep the modular trailers at a horizontal position during the transportation of cargo.

This suspension system can be adjusted to various positions to a point where the support system of the trailer gets 3 or 4 support points.

Points supporting

The different support points help in the realization of equal load distribution in each of the tyres. Moreover, this makes the transportation of heavy cargo safe and reliable even on a rugged terrain.

The suspension cylinders in the modular trailers are provided with two directions anti-break valves.

Once the pipeline is broken, the increasing fluid flow forms a differential pressure across the outlet and inlet port of the valve to block out the broken pipeline.

This will safely prevent the load from inclining to either side. Ultimately, this ensures stable transportation operations with the modular transporter.

Each of the wheel bogie with drive on the modular trailers have speed sensors attached to them. These micro-electric system tracks the sleep slip ratio of the driving wheels all throughout the transportation.

When the sleep slip ration goes beyond the set value, the sensor is able to detect that and send signals immediately. This has made the China Modular trailers attain a world-class safety requirement.

With this signal, changes in displacement of the driving motor are signaled hence ensuring that the rest of the other wheels with drive have the usual tractive force.

The modular transporters attain anti-skid controls and prevents the motors through the micro-electric sensors.

Skidding is hazardous for modular trailers as it may lead to a loss of cargo, lives and damages to the vehicle itself particularly in a case where the trailer will overturn.

Conclusion

In the world of modular trailers, the need for robust systems that can safely handle and transport heavy cargo from one location to the other has ever been on the increase.

The development of the China modular trailers has been fueled by the desired to have increased loading capabilities, precision control and steering, safety and efficient transportation.

Due to enhanced features of the China modular trailers, you can easily transport your cargo at faster speeds than has been the case with conventional haulers.

This is what makes the China modular trailers a world-class construction and acceptable in many parts around the world.

There is much research work and design that has gone into the development of such trailers hence a reason to consider using them in your operations.