Car carrier trailers have been around for some time now and you probably are wondering how best you can use them to transport cars from one point to another.

Well, it is important to first establish what they are and the options you got before finally choosing one of them for your application.

These is a kind of small trailers with a flatbed and are designed for the transportation of about 1-3 cars. This method is typically used for trucks, SUVs and modified cars.

But if you want to transport more than 4 sets cars at the same time, the car carrier trailer is your best choice.

In this post, you will know the key parts and designs of car carrier..

car carrier

So, what is a car carrier? Basically, a car carrier trailer is a type of trailer, which can at times be a semi-trailer and is designed for the efficient transport of passenger vehicles through a truck.

It is also known as a car hauler, an auto transport trailer or a car-carrying trailer among many other names as you will find out there in the market. Contemporary car carrier trailers are of many kinds.

They can be either open or enclosed. Most of the commercial trailers you will find out there have in-built ramps that are used for loading and unloading cars.

They also have power hydraulics used for raising and lowering ramps to enhance stand-alone accessibility. The commercial-size car carrier trailers are mainly used for shipping new cars from the producers to auto dealerships around the world.

Just like is the case with other semi-trailers, most of the commercial car carrying trailers are attached to a tractor by way of a fifth wheel coupling.

There are quite a number of options available for your choice and all this is based on the design applied in their manufacture. As a result, you will find options based on the following factors:

- Appearance of designs

- Different types of Axles

- Hydraulic Systems

Table of Contents

1. Appearance of Designs

There are two types of car carrier trailers in this category. This gives you an option to choose between them based on their appearance.

Each of the designs has its own advantages and disadvantages and therefore, it is important to weigh between these two prior to making your final choice on this matter. Here are the types based on how they appear.

- Frame body

- Packaged style

Get Detailed Specifications!

1.1 Frame Body

The frame body is ideally an open set up. This is the common skeletal tube steel design you will see on the roads. With this option, the vehicles are exposed to the environment.

However, it provides you with room for a larger carrying capacity. These commercial car carrying trailers usually have a double-decker arrangement.

Further on that, the decks are then subdivided into several storage and loading ramps. These ramps can be adjusted, lifted and tilted independently through the use of hydraulics.

Figure 1 Frame Body

With the frame body car carrier trailer, it is important to remember that your vehicle will basically be outdoors. That means it will be completely exposed during transportation.

It is no doubt that this is the most cheapest and common way of shipping vehicles. If you have a tight budget, it is the right method to ship your car especially if it is not a special type of vehicle.

All the same, there are important guidelines to be followed for the safe transportation of the same. Adhering to these guidelines is a standard practice that minimizes any chance of damage on the way.

See figure 1 above for a detailed look of the frame body car carrier trailer.

Key Advantages of the Frame style

- It’s easy to operate

- Its light and convenient to use

- Its cost effective

1.2 Packaged style

The common packaged car carrier trailer is usually made of by tarpaulin or steel. It is an enclosure mounted rigidly on a steel framework. This ensures that cars are kept clean and out of damage.

This is a type of enclosure constructed with walls matching a conventional box trailer. This affords your vehicles to be shipped under maximum protection.

However, this arrangement lowers the carrying capacity of the trailer due to limited storage and loading space.

Figure 2 Packaged Style

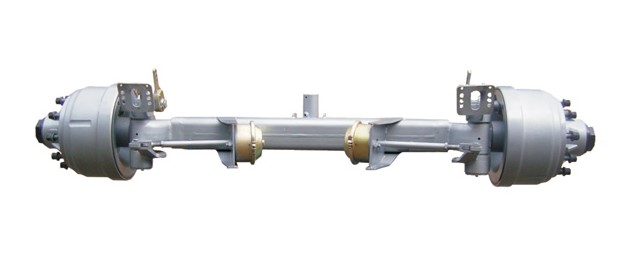

2. Different Type Of Axles

There are different axle configurations that can be found in the world of car carrying trailers today.

Each one of them is aimed at addressing a particular concern and therefore, you should take time to study them prior to choosing any one of them. Under this category of car carrier trailers, you can choose between the following:

- Expanded Axles

- Concave Axles

- Common Axles

Get Quotations!

2.1 Expanded Axles

For heavy weight applications having a rigid steel structure is good consideration.

However, it is not the only thing that you will need. More than that, you need to carry out stable operations that can only be guaranteed through stable platforms.

A car carrier vehicle with expanded axles makes it more stable during operation.

This is important in preventing side-turn accidents. Most importantly, the transpiration can be a lot faster due to the ability to move faster under stable conditions.

Unstable conditions will not only make the transportation unsafe but also slow.

The expanded axles car carrier trailer is adapted to serve you with a several benefits as would be needed in somewhat special cases.

It is typically used in some countries which have width-limit. It gives you the option to manage its size because its width is adjustable. Therefore, this is the option to consider if you are operating in such an environment.

2.2 Concave Axles

The stability of car carrying trailer can be attained through various designs. It can be attained by having expanded axles or by lowering the height of your carriage.

For this reason, the Concave Axles option lowers the overall height of the car carrier trailer. This has one major benefit as hinted above – it makes it more stable.

Stability is very important in these operations because it enhances the safety of your operations.

Figure 4 Concave Axles

2.3 Common Axles

There are some situations where your operations will not require specialized attention.

Therefore, it would not be a prudent effort to invest more on a trailer that is designed for transporting cars with a low clearance or with any other special considerations.

Therefore, car carrier trailers with common axles are the perfect choice for you.

You will find this type of a car carrier trailer in most parts of the world and is the widely used option because it can carry most of the cars transported around the world.

Ideally, it is very economical and durable option to use in the transportation of your vehicles.

Figure 5 Common Axles

3. Hydraulic System

Hydraulic systems have found a major application in our world today. It makes the loading and offloading of cargo highly possible in the shipping world.

In that case, the hydraulic system becomes very useful especially during operations.

With it, you can easily reduce the length of your car carrier trailer effectively and make necessary adjustments on the trailer to facilitate easy offloading and general operations.

With this option, you have the ability to control the up deck in order to descend through the hydraulic system. Once in the descend position, you can now drive the cars on it.

Figure 6

Many other benefits come with this type of car carrier trailer feature. With it, you can tilt the loading platform under the cars. This helps you save carriage spaces hence create room for cars.

The arrangement is also useful in reducing the length of the trailer hence help you meet the set laws and regulations in the industry that tend to vary from one region to another.

Typically, the trailer hydraulics permit the ramps to get aligned on a slope to facilitate the driving of cars upwards and secure them to the ramp floor using chains, wheel straps, or tie-down ratchets.

After that, the ramp can then be tilted through any direction for purposes of optimizing stacking of the cars.

To effectively load the cars on top of the trailer decks of a double-decker car carrier trailer, the rear half section of the deck can be tilted and again be lowered through hydraulic means.

This forms a drive-up ramp right through to the upper deck. The top deck is normally loaded first but then off-loaded last.

This is so done because the presence of vehicles on the lower deck makes it impossible for the operator to lower the top deck ramp.

The trailer hydraulics is managed through the use of a control box that is normally mounted on the same trailer.

Figure 7

Get Detailed Specifications!

3.1 Hydraulically Controlled Car Carrier Trailer Accessories

- Overflow Valve

This is a very important feature that manages the pressure in the hydraulic system. When the hydraulic pressure is too high, it automatically relieves it.

With an overflow valve pressure bypasses can be achieved to enhance the safety of your operations. This is needed to keep the system in check and avoid accidents.

This is so because the overflow valve is made with a sanitary design and is meant to deter risks and any possible failures that come with pressure surges in the hydraulic system.

Under normal conditions of operations, the overflow valve will remain closed.

Figure 8 Overflow Valve

The calibration of the valve is normally done to a predetermined pressure value through the regulation of the spring with a pressure nut.

The calibrated pressure is the set max safety pressure that is defined to prevent damage to the system resulting to failure and/or accidents.

Once the hydraulic pressure in the circuit goes past the calibrated pressure, the overflow valve will open and let the flow pass hence reducing the pressure of the system. This valve can include a handle meant to partially open up the valve.

- Controller

The controller is used for controlling every hydraulic platform of the car carrier trailer. This device provides you with an output signal of the hydraulic system inputs to help you make the necessary action.

The hydraulic control works in a similar principle as an electric controller. The only difference is the medium used.

This is a central point where the operator does all activities needed during the loading and offloading of vehicles on and off your car carrier trailer.

Figure 9 Controller

- Bracket

The bracket is used to carry the platform after raising the platform through the hydraulic system. Your car carrying trailer comes with both a lift and lock system.

This bracket is useful in locking the platform in position during transportation once the hydraulic lift mechanism sets the platform in the desired carrying position.

Figure 10 Bracket

This feature securely holds the platform carrying the vehicles in position making sure that they are safe from the point where they were load to their destination.

Therefore, there is nothing to worry about once the bracket is in place. As you conduct checks for the rest of the other features, this will be something to check out as well.

Figure 11 Bracket

The Bottom Line

Contemporary car carrying trailers come in different sizes and shapes to address any conceivable needs in car transportation. Car carrier trailers are typically built to haul either multiple cars or single cars.

Therefore, it is important to identify your needs first. Don’t settle for any one of them until you have established what you actually need to meet the kind of need that you have.

If you have a special car with a low clearance, you may not need a car carrier trailer. A flatbed trailer without decks would be the best option in such a case.

There are quite a number of features to check and it is therefore importance to establish their performance at all times. Most of the car carrier trailers have in-built ramps that facilitate the loading and unloading of the transported vehicles.

The ramps are normally raised and lowered through the use of power hydraulics and therefore, it is also an important feature to assess. With the advent of technology and innovation, more superior features are coming up.

The car hauling industry has undergone a lot of transformation hence the importance to stay informed of these developments.

This guide aims at enlightening you on these key characteristics of car carrier trailers and their performances.

Hi I want a car carrier for my truck hino 500 2626 12ton, a car carrier than can pick up 7cars at a time please give me quotation.

Am leaving in south Africa Johannesburg.